Short Range Bars

801 ANTI-STATIC TINSEL

Copper Anti-Static Tinsel is a traditional and effective

method of neutralising static electricity.

It is commonly used to neutralise sheets and webs

throughout industry. 801 Tinsel must be connected to earth

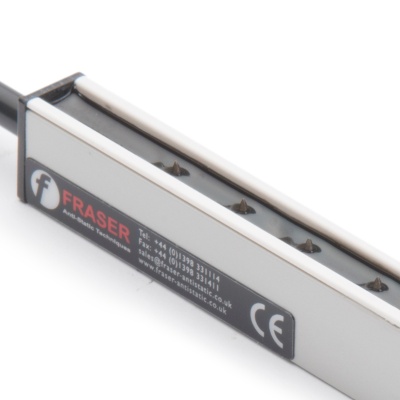

1100 SERIES STATIC ELIMINATORS

The 1100 Series Static Eliminators are brand new high performance ionisers for modern manufacturing. A resistive coupling between the high voltage source and the emitters gives them powerful ionisation with completely shockproof operation.

Available in two versions: the 1100 with fixed M4 mounting studs and the 1100-S with mounting studs which slide in a slot to the required position. Their compact size makes them particularly suited to web and sheet applications where space is limited.

- Operating distance from 20mm to 100mm.

- Suitable for most industrial processes, including pharmaceutical and food manufacturing.

- Simple to install, with fixed or variable mounting studs.

- All electronic components encapsulated in epoxy resin for protection and maximum durability, giving the Bar an IP66 rating, and suitable for wash down applications.

1250 & 1250-S STATIC ELIMINATORS

Powerful performance and market-leading reliability make the 1250 and 1250-S the first choice static eliminators for major manufacturers.

The 1250 and 1250-S neutralise static electricity on sheet, web and similar processes throughout the plastics, packaging, converting and related industries.

-

- The modern design gives high performance and completely shockless operation.

- Stay-sharp etched emitters for better long term performance.

- Emitters at 10mm pitch provide the most intense field of static neutralisation.

- All electronic components are fully encapsulated for maximum reliability.

- They are suitable for food, medical, pharmaceutical and many cleanroom applications.

- Robust construction ensures a long life of high performance.

- Simple to install with fixed mounting studs (1250) or studs sliding in slot (1250-S).

- Operating distances of up to 150mm, best distance 20 50mm.

- Washable and easy to clean.

EX1250 - Atex Certified Static Eliminator

The EX1250 Bar is a high performance static eliminator with ATEX certification for use in hazardous areas.

Maximum ionisation performance in a hazardous area.

- The EX1250 is part the Fraser 1250 family of static eliminators, which offer market-leading reliability and performance.

- Stay-sharp etched emitters for better long term performance. Life 5 years +. Non-infectious.

- Emitters at 15mm pitch provide more ionisation and so better neutralisation.

- Robust construction, but compact and easy to install.

- Operating distance up to 150mm. Best distance for high speeds and high charges 25mm - 50mm.

- Washable and suitable for food, medical and pharmaceutical applications.

- All electronic components are fully encapsulated for maximum reliability.

- Certified for Zones 1, 2 and 22. Gas group IIB (ethylene).

1260 & 1265 IONISING ELECTRODES

Very compact, high performance static eliminators suitable for neutralising the static charge on small objects and in restricted spaces.

The 1260/1265 are used to neutralise static electricity on tape, trim, yarns, optical fibres and other small parts.

- The resistively coupled design produces a large volume of ionisation for neutralising fast-moving products and high charges.

- It is completely shockproof in operation.

- The design geometry projects the ionisation to give an operating distance of up to 150mm. The best performance is between 25mm to 50mm.

- All critical parts are encapsulated in epoxy resin for a long life.

- Compact and easy to install.

- Can be used in to ionise existing air nozzles and jets.

FRASER X-12F

The X-SERIES range of static eliminators is a major advance in industrial static control technology. X-SERIES intelligence monitors the static charge and reacts to it by emitting the quantity and polarity of ions for fastest neutralisation. X-12F should be mounted within 100 mm of the charged material.

FRASER X-Series Operating Instruction manual

It replaces the NEOS 12F

- 12 kV of ionising power from 24 V DC input.

- X-SERIES reactive intelligence sets new levels of static neutralisation performance.

- Compact size with fully encapsulated electronics.

- Shockless, tungsten emitters guarantee a long life.

- 100 % coverage: overall length = effective length.

- X-SERIES intelligence has three automatic and three manual settings, giving the operator the ability to

optimise performance for actual conditions. - Local LED indication of status of Bar and whether it needs cleaning. Duplicate signals for PLC or to power external lamps, relays.

- Remote on/off switching and standby mode.

3024 F 24VDC IONISING BAR

A compact and powerful static eliminator, with built-in electronics, 24VDC supply and powerful performance. Static neutralisation to meet the requirements of high performance machinery. Integrated high voltage power supply, requires only a low voltage 24V DC input.

-

- Shockless, resistively coupled emitters made in tungsten for unlimited life.

- LED status indication: Bar OK: (green), fault (red).

- Remote monitoring of operational status.

- 100% coverage. Effective length = Overall length. No dead zone.

- Standard M8 4 pin connector.

- Available in two versions: 1. 3024 F high speed version for speeds up to 1,300m/min, for distances from 25mm to 150mm. 2. 3024 L long range version for distances from 100mm to 500mm

-

3024 Operating & Installation manual

3014 COMPACT SHORT RANGE 24 V DC STATIC CONTROL BAR

Market leading performance in a very compact Bar for compatibility with modern machinery. Integrated high voltage power supply, requires only a low voltage 24 V DC input.

The 3014 represents another leap forward in DC Static Control technology from Fraser Anti-Static Techniques. This compact 24 V DC static eliminator is an ideal (and more powerful) alternative to traditional AC powered static control bars. The compact profile allows the bar to be situated closer to the material being treated and more easily integrated with modern machinery designs. To discuss your requirements and determine that the 3014 would be a suitable compact static eliminator for your situation, please download the data sheet and contact an engineer at Fraser Anti-Static today.

- Emitters made from tungsten for best long term performance; Resistively coupled for shockless operation.

- LED status indication: Bar OK: (green), fault: (red). Clean Me: (alternating red/green).

- Remote monitoring of operational status and cleanliness through 24 V signals.

- Effective length = 20 mm less than overall length.

- Standard M8 4 pin connector.

- Best operational distance: 20 mm to over 150 mm.

3014 Operation & Installation Manual

3024 COMPACT 24V DC SHORT-RANGE ANTI-STATIC IONISING BAR

The 3024 Compact 24V DC short-range static eliminator bar meets the requirements of high-performance machinery where space is constrained.

It is the only bar available at this scale* with built-in electronics and delivers powerful static elimination at close range to a substrate or other material. The 3024 Compact delivers up to 7.5kV integrated in the bar and is ideal for fast moving materials at speeds up to 1300m/min. Its flexibility makes it suitable for most industrial processes, including pharmaceutical and food manufacturing, and it is particularly well suited to web and sheet applications where space is limited.

- A choice of 150mm or 200mm lengths.

- Optimum operating distance of 20mm to 50mm and maximum 150mm.

- 100% coverage. Effective length = Overall length. No dead zone.

- Shockless, resistively coupled tungsten emitters for unlimited life.

- Suitable for material speeds up to 1,000m/min.

- LED status indication: Bar OK (green), fault (red).

- Remote monitoring of operational status.

- Standard M8 4-pin connector.

- Protected against undervoltage, overload and reverse polarity.

- An air boost bar option is also available.

- CE and UL.

-

3024 Operating & Installation manual

3024 ULTRA-COMPACT 24V DC CLOSE-RANGE STATIC ELIMINATOR

The 3024 Ultra-Compact 24V DC close-range static eliminator is designed for use in high-performance machinery where space is at a minimum. Ion balance makes it suitable for most industrial applications where static control is imperative.

It has built-in high voltage electronics to deliver powerful static elimination at close range to a substrate or other material. It is capable of delivering up to 7.5kV from a low voltage 24 V DC input. Pulsed DC high voltage provides excellent charge decay performance even at longer distances.

Integrated mounting holes make it easy to install and retrofit to machines, and it can be monitored remotely to maximise performance.

The 3024 Ultra-Compact can also be combined with nozzles and gun handles to form ionised air cleaning devices.

- Perfect for small spaces at just 80mm x 47mm x 16mm (excluding connector).

- Ideal operating distance of 20mm to 150mm.

- Shockless, resistively coupled tungsten emitters for unlimited life.

- LED status indication: Bar OK (green), fault (red), red flash (standby), green/red flash (attention required).

- Remote monitoring of operational status; outputs compatible with IEC 61131-2 Type 3 PLC inputs.

- Standard M8 4-pin connector.

- Protected against under-voltage, overload and reverse polarity.

- External AC-DC PSU available where 24 V DC not available.

- CE and UL.

Producing high voltage, low current in a controlled and safe way is the primary function of each Fraser Anti static Power Unit.

Our power units allow multiple AC products to be connected, requiring only a straightforward mains input.

There are a range of power units available depending upon size, load, capacity and total number of outputs required.