Industry Standard Ratings

An Ingress protection is a way of showing how effective an item is at blocking out foreign bodies. The IP stands for Ingress Protection and the following numbers (i.e. IP67, IP56, etc) refer to the protection an item offers against the intrusion of the two categories of foreign bodies, i.e. solid (e.g. dust) and liquid (water).

IP ratings chart

The National Electrical Manufacturers Association (NEMA) defines standards used in North America for various grades of electrical enclosures typically used in industrial applications. Each is rated to protect against personal access to hazardous parts, and additional type-dependent designated environmental conditions. A typical NEMA enclosure might be rated to provide protection against environmental hazards such as water, dust, oil or coolant or atmospheres containing corrosive agents such as acetylene or gasoline.

Neema ratings chart

UL (Underwriters Laboratories) Listing means that UL has tested representative samples of a product and determined that the product meets specific, defined requirements. These requirements are often based on UL's published and nationally recognized Standards for Safety.

UL Standards encompass UL's extensive safety research and scientific expertise. With over a century of experience in the development of more than 1,500 Standards, UL is an accredited standards developer in the US and Canada. In extending its global public safety mission, UL Standards partners with national standards bodies in countries around the world to build a safer, more sustainable world.

UL Wikipedia website

Thermocouple Colour Codes

Thermocouples of all different types have their own colour coding to aid identification however this is not necessarily as easy as it may seem. As well as each thermocouple type having its own colour code, there are various national and international standards each having their own colour code system. It is important to positively identify which standard is being used before you can identify the thermocouple type. Don’t worry though, we are always here to help you.

The primary standard used within the UK and Europe is often referred to simply as the IEC colour code. Strictly speaking this is a little vague as this refers to the IEC standard IEC584 and more specifically IEC584-3. This is now an old standard and the current standard used within the UK and Europe is BS EN 60584 and the part of this standard which deals with colour codes is BS EN60584-3:2008.

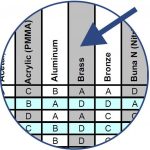

Chemical Compatibility Reference Chart

Reference table for checking Chemical compatibility with various materials.

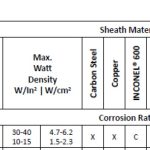

Maximum Watt Density for Materials Chart.

With additional sheath material compatibility reference

Terminal Stud Hole Size Reference Chart

Cross reference U.S Imperial stud sizes with metric equivalent.

Trade tariff Commodity codes to classify goods for Import & Export.

Goverment website for calculating goods Commodity codes.

Page link to commodity codes for goods supplied by Sensemaster.

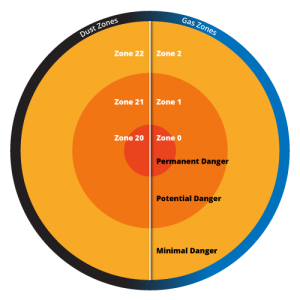

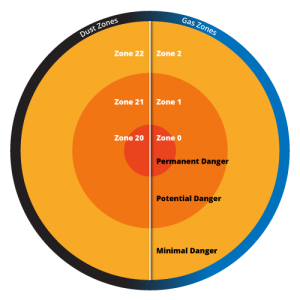

HAZARDOUS GAS, VAPOUR AND MIST ENVIRONMENTS: ATEX ZONES 1 AND 2

A good example of an ATEX Zone 1 or ATEX Zone 2 classified operation would be a chemical or petrochemical plant, where there is a heightened risk for explosion during the course of normal day to day operations. Within a hazardous gas environment an explosion can take place if a flammable substance, an oxidiser and a source of ignition are found simultaneously within the atmospheric air. The absence of any one of these three elements would stop an explosion from occurring, and that is why through continued innovation and increased focus on safety the lifting equipment industry is able to offer a broad range of explosion proof and spark proof hoists, winches and trolleys, etc. specifically for safe use in these hazardous environments.

Zone 1 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours and mists is likely to occur occasionally during normal operation’, whereas Zone 2 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours and mists is not likely to occur in normal operation but if it does occur, it will be present for a short period of time only’.

HAZARDOUS DUST ENVIRONMENTS: ATEX ZONES 21 AND 22

ATEX Zones 21 and 22 are specific to hazardous dust environments, like can be found in the food industry in, for example, a flour mill where explosible dusts are often present. Some examples of explosible dusts within the food industry alongside flour are custard powder, instant coffee, sugar, dried milk, potato powder and soup powder as a solid substance that is finely ground may ignite more readily or a lower energy. The risk within the food industry with hazardous gas environments is that if any combustible substance is mixed or suspended in air at the correct concentrations and contained in a vessel or building when ignition occurs, then the result can be a violent explosion.

In a hazardous dust environment, an ATEX Zone 21 is classified as an area that is classified ‘as a place in which an explosive atmosphere in the form of a cloud of combustible dust in the air is likely to occur occasionally during normal operation’ whereas an ATEX Zone 22 is classified as 'a place in which an explosive atmosphere in the form of a cloud of combustible dust in the air is not likely to occur in normal operation but if it does occur, it will be present for a short period of time only’. Within any ATEX rated zone there is significant importance placed on safety and the necessity of spark proof/explosion proof hoists and lifting equipment is paramount.