Point Level Measurement For Liquids

There are several principles for measuring Point levels in liquids:

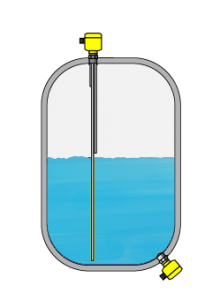

VIBRATION

Function

The basis of point level detection with vibrating level switches is a tuning fork, i.e. a vibrating fork. If the vibrating probe comes into contact with the medium, the oscillation rate changes and the vibrating level switch outputs a switching command. Vibrating level switches are used as overfill protection or empty alarm.

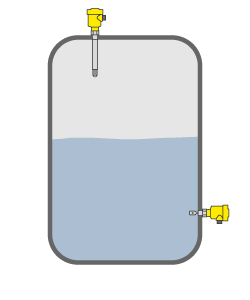

CAPACITIVE

Function

In capacitive point level measurement, capacitive sensor and vessel form the two electrodes of a capacitor. Any change in capacitance due to a level change is converted into a switching signal. Thanks to shortenable cable and rod versions, the level switches can be adapted to any application and often serve as overfill protection, dry run protection, oil/water detection and foam detection.

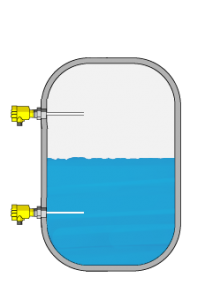

CONDUCTIVE

Function

When the electrodes of the conductive point level sensor come into contact with a conductive liquid, a small alternating current begins to flow. The electronics responds by triggering a switching command. Conductive point level sensors are used in all areas of industrial metrology, e.g. as overflow protection, pump control or dry run protection.

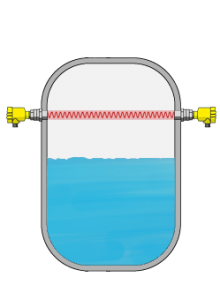

RADAR

Function

The microwave barrier works like a light barrier: If the microwave beam between transmitter and receiver is blocked by the medium, the measuring signal is damped. This change is detected by the receiver and converted into a switching signal.