Circulation Heaters

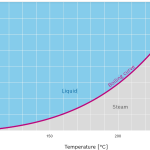

Water to Steam Pressure versus Temperature.

The different temperatures required to turn water into steam with varying pressure. Click on link above for a PDF Table Download.

FLUENT® In-Line Heater

Watlow’s new FLUENT in-line heater is a small, lightweight, high-performance heater that can replace both a traditional immersion type heater or a heater wrapped around a tube as part of a thermal system. Watlow’s FLUENT heater is designed as an integrated solution that replaces multiple components in a system. This heater design reduces overall system cost and complexity. Because of its high watt density, it offers ultra-fast response leading to higher system performance.

Featuring Watlow’s patented thermal spray technology, the heater makes use of its entire surface to produce heat, which optimizes heat transfer and temperature uniformity.

Online Configurator

Fluent Heater technical drawings PDF downloads

Fluent Product Guide

Fluent Quick Start Guide

Screw Plug Circulation Heaters

Circulation heaters provide a ready-made means to install electric heating with a minimal amount of time and labor. This is accomplished by combining heating elements, vessel, insulation, terminal enclosure, mounting brackets and inlet and outlet connections into a complete assembly.

Made from NPT screw plug heater assemblies mated with a pressure vessel (tank), circulation heaters are designed to heat forced-circulation air, gases or liquids. Ideal for either in-line or side-arm operations, these assemblies direct fluids past FIREBAR or WATROD heating elements, to deliver fast response and even heat distribution.

Installation & Maintenance Manual for Watrod or Firebar Heaters PDF Download

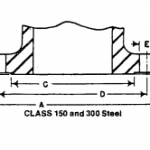

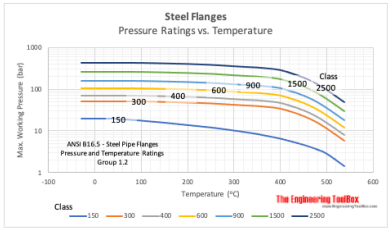

3'"-8" Flange Heaters

Circulation heaters provide a ready-made means to install electric heating with a minimal amount of time and labor. This is accomplished by combining heating elements, vessel, insulation, terminal enclosure, mounting brackets and inlet and outlet connections into a complete assembly.

Made from ANSI flange heater assemblies mated with a pressure vessel (tank), circulation heaters are designed to heat forced-circulation air, gases or liquids. Ideal for either in-line or side-arm operations, these assemblies direct fluids past FIREBAR or WATROD heating elements, to deliver fast response and even heat distribution.

Installation & Maintenance Manual for Flange/Circulation Heaters PDF Download

10'"-14" Flange Heaters

Circulation heaters provide a ready-made means to install electric heating with a minimal amount of time and labor. This is accomplished by combining heating elements, vessel, insulation, terminal enclosure, mounting brackets and inlet and outlet connections into a complete assembly.

Made from ANSI flange heater assemblies mated with a pressure vessel (tank), circulation heaters are designed to heat forced-circulation air, gases or liquids. Ideal for either in-line or side-arm operations, these assemblies direct fluids past FIREBAR or WATROD heating elements, to deliver fast response and even heat distribution.

Watlow meets virtually all your circulation heater assembly needs with made-to-order units. These units can be made from a wide range of heating element sheath materials, wattages, vessel sizes and materials, pressure ratings, terminal enclosures and controls.

Installation & Maintenance Manual for Flange/Circulation Heaters PDF Download

OPTIMAX® Heat Exchanger

Watlow has over 40 years of experience designing and manufacturing heat exchangers, and we have the knowledge, experience and expertise required to create optimal heating solutions. Watlow has taken the tried and true, critical design criteria and improved it to create a new generation heating technology – the OPTIMAX Heat Exchanger.

Watlow’s new OPTIMAX technology combines optimal fluid dynamics, efficient heat transfer, low pressure drop and a compact and reliable package to create a world-class system solution.

Watlow’s EFD (enhanced fluid dynamic) technology provides advanced flow throughout the system without compromising the integrity of the fluid, heating elements and/or vessel. Fluid temperatures are further optimized through the use of OFT (optimized film temperature) technology in the heating elements. These, coupled together, provide an accelerated heat transfer rate allowing the vessel to perform consistently at shorter lengths, or smaller shell diameters. In addition, the OPTIMAX can be designed for backwards compatibility with existing designs.

HYDROSAFE® Heat Exchanger

HYDROSAFE®, Watlow’s new indirect electric heat exchanger for dry gas seal applications, has been designed as a standardized thermal solution that minimizes custom engineering requirements because it can be adapted to a variety of conditions. The HYDROSAFE provides very flexible heating capabilities (12 to 31.2 kW) to compensate for changes in gas flow rates, or changes in gas composition, when interconnected to our purpose engineered WATCONNECT™ control panel. Multiple units may be connected in series for higher kW needs.

The HYDROSAFE holds complete assembly hazardous certifications with a "touch-safe" exterior versus competitors that offer enclosure-only certifications.

The seal gas is heated inside a small diameter seamless formed cylinder to allow for high system pressure capability requirements. In addition to high pressure capabilities, up to 6800 psi (469 bar) in the standard offering, the heater is up to 50 percent smaller than comparable circulation heaters. The empty weight of the HYDROSAFE heater is about 300 pounds (136 kgs) maximum. This small footprint and weight allow the user to reduce the cost of the supporting super structure on rigs, platforms, FPSOs, vessels, etc. Indirect technology means there is no concern about your seal gas stream ever coming into contact with the heating elements, especially when elements reach end-of-life conditions and are typically more susceptible to corrosion. The small diameter and low volume pressure boundary allow use in many countries without the need for further pressure vessel certifications.

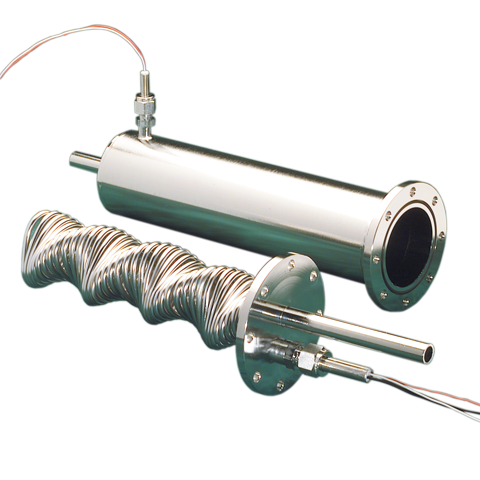

STARFLOW™ Circulation Heaters

The STARFLOW circulation heater is engineered to heat a flowing gas stream to 1000°F (537°C). The circulation heater's 316L stainless steel chamber houses a small diameter sheathed element, which allows for quick response to both heat-up and cool down cycles.

Watlow's starwound, coiled cable heater provides extremely efficient and reliable heating by maximizing the contact area of the gas or fluid with the element. Because the element is sheathed, the unit can operate in gas streams requiring a clean environment as well as atmospheres containing contaminants and moisture.

This circulation heater provides superior performance compared to units with internally exposed or open element wires.

Cast Aluminium Circulation Heaters

CAS’s family of heaters are ideal solutions for demanding applications. These heaters consist of a helical coiled tube and tubular element cast into an aluminum body. The aluminum body serves as the heat transfer media between the tubular element and the coiled fluid or gas transfer tube. The unique construction of the heater allows it to be used where thermally sensitive materials such as paints and resins or flammable materials such as fuels and solvents are being heated.