Air Fan & Boost

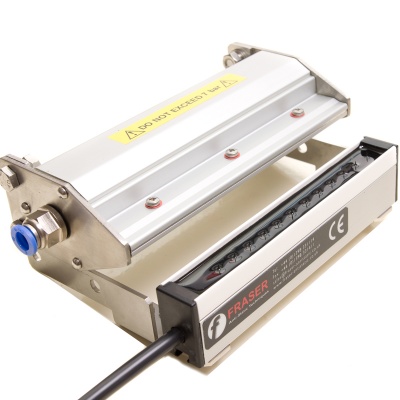

1250 AIR BAR STATIC ELIMINATOR

The 1250 Air Bar uses low pressure compressed air to extend the effective static neutralisation range of the 1250 Bar to over 500mm.

Typical applications for the 1250-Air Bar are stopping film sticking to rollers on packaging machines, keeping sensors clean and free of static, neutralising mouldings on conveyors and many others.

- The 1250-Air Bar has all the advantages of the 1250-S Bar with the assistance of an airflow which extends the neutralisation distance to over 500mm.

- It is used for blowing ionised air into a restricted area, onto a product which moves in position or onto a substantially 3-dimensional product.

1250 AB AIRBOOST STATIC ELIMINATOR

The 1250-AB Bar uses low pressure compressed air to extend the effective static neutralisation range up to 500mm.

Typical applications for the 1250-AB are stopping film sticking to rollers on packaging machines, keeping sensors clean and free of static, neutralising mouldings on conveyors and many others.

- The 1250-AB has all the advantages of the 1250-S Bar with the assistance of an airflow which extends the neutralisation distance up to 500mm.

- It is used for blowing ionised air into a restricted area, onto a product which moves in position or onto a substantially 3-dimensional product.

2010 IONISED AIR BLOWERS

Model 2010 Ionised Air Blowers are long distance static eliminators with a robust stainless steel construction and powerful ionisation performance.

2010 Blowers produce a high volume of ionised air to neutralise static charges in a wide variety of industrial applications.

- Robust stainless steel construction for a long trouble-free life.

- Ionisation is provided by two 1250 Bars, mounted in the mouth for fast, market-leading static neutralisation.

- Integrated Power Unit for sizes 50cm and above.

- Sizes available from 305mm, 500mm then up to 2m in steps of 250mm.

- The Ionised air leaves the blower and expands at approximately 15 degrees in both axes.

- Swivel L brackets allow for versatile mounting.

2050 IONISED AIR BLOWER

High specification Ionised Air Blower with integrated power unit and controls.

High performance to meet the demanding requirements in the electronics, medical, pharmaceutical and RFID industries.

- High Performance with excellent electrical balance +/- 30V is standard for this model.

- Visible alarm if there is non-function of the unit. LEDs showing operational condition: green = ok, red = fault.

- Portable and easy to install with adjustable stand for mounting versatility.

- Long life tungsten emitters. Replaceable if damaged.

- Adjustable airflow up to 170m3 /hr(100cfm)

- High performance axial fan, ball bearing, with life expectancy of 120,000 hours at 40ø.

Available in three multifan versions

- 2052 - 510mm long with two fans.

- 2053 - 780mm long with three fans.

- 2054 - 1050 mm long with four fans.

High specification multifan Ionised Air Blowers with integrated power unit and controls.

High performance ionisation to meet the demanding requirements in the electronics, medical, pharmaceutical and RFID industries.

- High Performance with excellent electrical balance +/- 30V is standard for this model.

- Visible alarm if there is non-function of the unit. LEDs showing operational condition: green = ok, red = fault.

- Portable and easy to install with adjustable stand for mounting versatility.

- Long life tungsten emitters. Replaceable if damaged.

- Adjustable airflow up to 170m3/hr (100cfm) per fan.

- High performance axial fan, ball bearing, with life expectancy of 120,000 hours at 40ø.

Available in three multifan versions

- 2052 510mm long with two fans.

- 2053 780mm long with three fans.

- 2054 1050 mm long with four fans.

5000 & 5100 IONISED AIR KNIVES

Ionised Air Knives produce fast-moving ionised air which can neutralise static electricity and remove contaminants.

They are used to clean plastic parts removing the dust and eliminating the static electricity to prevent re-attraction.

- Powerful ionisation kills the static charge holding the dust, allowing the fast beam of laminar air to remove it for a thorough cleaning.

- The non-turbulent laminar airflow limits the recombination of ions in the air and so maximises the static neutralisation performance.

- Compressed air is amplified by a factor of up to 20:1. So a litre of compressed air produces up to 20 litres of fast-moving air.

- Available in a wide range of standard lengths in two body styles the compact 5000 and the efficient 5100. See datasheet for further details.

- The 1250 Static Eliminator Bar mounted on the air knife has market leading reliability: see datasheet on 1250 Static Eliminator for further details.

- Simple to install and regulate.

5500 IONISED AIRKNIFE

High performance fan-driven Ionised Airknives for static neutralisation and cleaning of mouldings, glass, automobiles and other large objects.

The blower produces a high volume of air which exits from the airknife in a fast laminar flow. Fraser design and supply 5500 Ionised Airknife Systems to meet the most demanding applications.

- The system consists of one or more ionised airknives connected to an external blower.

- Static neutralisation power up to 50% better than competitive systems to break the electrostatic bond between the dust and surface and to prevent re-attraction of dust.

- Air cleaning speed of 110m/sec at the slot of the airknife for thorough and powerful cleaning.

- Longer range cleaning power than compressed air systems.

- More performance per kilowatt of power. For example, competitors offer 7.5kW motors to match the performance of our 5.5kW motors saving the customer money every minute of operation.

- Cost saving of up to 70% compared to other systems.

6000 IONTUBE

The 6000 Iontube is designed to be incorporated into pneumatic transport systems to neutralise the static electricity generated in this process.

The 6000 Iontube can increase dramatically the efficiency of dust and product separation in cyclones; it can eliminate static charge build-up in hoppers and collection system preventing blockages and handling problems.

-

- Static neutralisation is supplied by Ionising Bars mounted in enclosures around the circumference of the Iontube. The number of Bars is determined by the diameter and length of the Iontube.

- The Bars are individually connected to a connector box mounted on the Iontube. So if one bar is damaged, only that bar needs to be replaced.

- Standard 6000 Iontubes use 1m long Jacob stainless steel tubes. These are available in a wide range of standard sizes with coupling devices for easy incorporation into existing pipe work, see www.jacob-tubing.com.

- We can make Iontubes in other materials and sizes please contact the factory with your requirements.

4900 ROTO-CLEAN

Roto-Clean features the latest ionising technology from Fraser to neutralise static and blast away dust and contaminants

- Removes charge, cleans and prevents re-attraction of dust

- Better cleaning with lower compressed air cost

- Higher quality output with less rework

4300 in-line compressed air ioniser

The 4300 is an in-line compressed air ioniser for use where the ionisation of an existing air supply, in an ordinary compressed airline, is required. This system can be used where compressed air is deployed to remove electrostatic contaminants or air separation systems are fitted to sheet feeding decks.

- Ionises the air in flexible pipework with 5.5 – 6 kV of ionising power provided by a 1265 Single Point Ioniser

- If positioned close to the discharge end, the recombination of ions will reduce and effectiveness increase

- Easy to install – standard air fitting is for 10 mm ID flexible airpipe; alternatively, the ¼” BSP female thread could be used for the customer’s air fittings and pipework

- Air fittings and pipework must be plastic and as large as possible to maximise life of ionised air in the pipe

Producing high voltage, low current in a controlled and safe way is the primary function of each Fraser Anti static Power Unit.

Our power units allow multiple AC products to be connected, requiring only a straightforward mains input.

There are a range of power units available depending upon size, load, capacity and total number of outputs required.