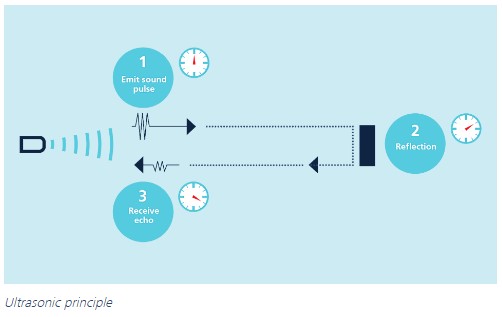

Ultrasonic principle

Ultrasonic sensors emit short, high-frequency sound pulses at regular intervals. These propagate in the air at the velocity of sound. If they strike an object, then they are reflected back as echo signals to the sensor, which itself computes the distance to the target based on the time-span between emitting the signal and receiving the echo.

As the distance to an object is determined by measuring the time of flight and not by the intensity of the sound, ultrasonic sensors are excellent at suppressing background interference.

Virtually all materials which reflect sound can be detected, regardless of their colour. Even transparent materials or thin foils represent no problem for an ultrasonic sensor.

Typical ultrasonic sensors are suitable for target distances from 20 mm to 8 m and as they measure the time of flight they can ascertain a measurement with pinpoint accuracy. Some of our sensors can even resolve the signal to an accuracy of 0.025 mm.

Ultrasonic sensors can see through dust-laden air and ink mists. Even thin deposits on the sensor membrane do not impair its function.

Sensors with a blind zone of only 20 mm and an extremely thin beam spread are making entirely new applications possible today: Fill level measurement in wells of microtiter plates and test tubes, as well as the detection of small bottles in the packaging industry, can be implemented with ease. Even thin wires are reliably detected.