Specialty Heaters

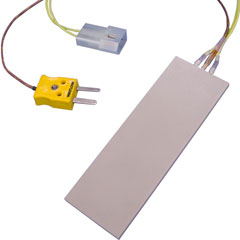

ULTRAMIC® Advanced Ceramic Heaters

Technical Drawings of available stock

Resistance vs Temperature Ultramic Heaters 130.5 Ohm @ RT

Ultramic Mounting Instructions

Vibration & life information

The ULTRAMIC® ceramic heaters from Watlow® are designed for thermal applications where the high performance of an advanced ceramic heater is required to ensure optimal effectiveness of the equipment and process.

ULTRAMIC ceramic heaters are constructed of aluminum nitride (AlN) and incorporate a thermally matched proprietary heating element that provides maximum performance in challenging applications. AlN is especially suitable for applications requiring a clean, non-contaminating heat source. Additionally, the excellent geometric stability ensures consistent part-to-part thermal contact during heating cycles.

Watlow AlN ceramic heaters can operate up to 400°C (752°F) with an ultra-fast ramp rate of up to 150°C (270°F) per second depending on the application, heater design and process parameters. In addition to excellent thermal characteristics, ULTRAMIC ceramic heaters have high electrical isolation and typically provides superior chemical resistance as compared to traditional metal heaters.

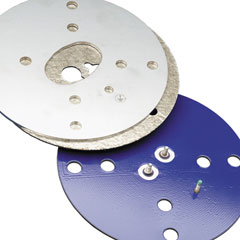

Thick Film Conduction Heaters

Watlow's 430 stainless steel thick film conduction heaters are ideal for use in many applications where fast response and uniformity are essential. A clamp-on thick film heater provides the best possible combination of heat transfer, thermal efficiency and temperature uniformity.

These high performance film heaters use thick film technology to provide maximum temperature response in a low profile package. This film heater technology can be applied in areas where space is at a premium or where conventional heaters cannot be used because of limited voltage and wattage combinations.

Thick film conduction heaters provide a low-profile heater in a variety of shapes. These shapes include two-dimensional circular and rectangular forms. Due to the direct surface contact, a thick film heater ensures efficient heat transfer through thermally stable substrates and precise resistance trace patterns.

Coil and Cable Heaters

The versatile Watlow coil/cable heater can be formed into a variety of shapes. Cable heaters are small diameter, high-performance units, fully annealed and readily bent to a multitude of configurations.

The cable heater can be formed into a compact, coiled nozzle heater supplying a full 360 degrees of heat with optional distributed wattage. A straight cable heater can snake through an equipment application. Flat spiral configurations can be used in high-tech manufacturing while a star wound cable can be used for air and gas heating.

Different applications require different construction methods, including one, two or four resistance wires; parallel coil or straight wire; drawn or swaged sheaths; with or without internal thermocouples; leads exiting from one or both ends, and round, rectangular or square cable cross sectionals.

Whatever the application, the Watlow coil heater and cable heater can be shaped to fit.