Point Level Measurement Bulk Solids using Vibration

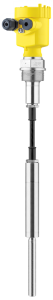

VEGAVIB 61

It detects the limit level reliably and with millimetre accuracy directly at the mounting position. The smooth surface of the vibrating rod, without sharp corners or edges, prevents bulk material from getting stuck or jammed and is easy to clean.

The VEGAVIB 61 is a level switch for granular and coarse-grained bulk solids. The VEGAVIB 61 detects reliably and accurately the min. or max. limit level. The smooth surface of the vibrating rod, without corners and edges, avoids jamming of the bulk solid and is easy to clean.

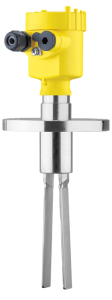

VEGAWAVE 61

It detects the limit level reliably and with millimetre accuracy directly at the mounting position. The tuning fork design is very robust and unaffected by buildup. Grain size: max. 10 mm

The VEGAWAVE 61 is a level switch for universal use in powders and fine-grained bulk solids. The level switch detects reliably and robust the min. or max. limit level. The tuning fork is ideal for use either in adhesive and abrasive products as well as in bulk solids with very low density.

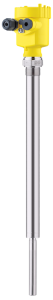

VEGAVIB S61

Pre-configured lengths of 150, 500, 1000 or 1500 mm available. Limited choice of electronics and approvals.

The VEGAVIB S61 is a level switch for granular and coarse-grained bulk solids. The VEGAVIB S61 detects reliably and accurately the min. or max. level. The smooth surface of the vibrating rod, without corners and edges, avoids jamming of the bulk solid and is easy to clean.

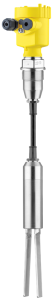

VEGAWAVE S61

Pre-configured lengths of 150, 500, 1000 or 1500 mm available. Limited choice of electronics and approvals.

The VEGAWAVE S61 is a level switch for universal use in powders and fine-grained bulk solids. The level switch detects reliably and robust the min. or max. level. The tuning fork is ideal for use either in adhesive and abrasive products as well as in bulk solids with very low density.

VEGAVIB 62

The position of the switching point can be up to 80 m away from the installation site. The smooth surface of the vibrating rod, without sharp corners or edges, prevents bulk material from getting stuck or jammed and is easy to clean.

The VEGAVIB 62 is a level switch for granular and coarse-grained bulk solids. The optimized rod design without corners and edges avoids jamming of the bulk solids and is easy to clean. The VEGAVIB 62 detects reliably and accurately the min. or max. limit level in bulk solids. The position of the switching point is specified flexibly through the length of the suspension cable.

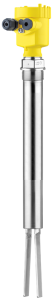

VEGAVIB 63

The position of the switching point can be up to 6 m away from the installation site. The smooth surface of the vibrating rod, without sharp corners or edges, prevents bulk material from getting stuck or jammed and is easy to clean.

The VEGAVIB 63 is a level switch for granular and coarse-grained bulk solids. The VEGAVIB 63 detects reliably and accurately the min. or max. limit level. The smooth surface of the vibrating rod, without corners and edges, avoids jamming of the bulk solid and is easy to clean. The position of the switching point is specified through the tube extension.

VEGAWAVE 62

The position of the switching point can be up to 80 m away from the installation site. The tuning fork design is very robust and unaffected by buildup. Grain size: max. 10 mm

The VEGAWAVE 62 is a level switch for universal use in powders and fine-grained bulk solids. The level switch detects reliably and robust the min. or max. limit level. The tuning fork is ideal for use either in adhesive and abrasive products as well as in bulk solids with very low density. The position of the switching point is determined through the length of the suspension cable.

VEGAWAVE 63

The position of the switching point can be up to 6 m away from the installation site. The tuning fork design is very robust and unaffected by buildup. Grain size: max. 10 mm

The VEGAWAVE 63 is a level switch for universal use in powders and fine-grained bulk solids. The level switch detects reliably and robust the min. or max. limit level. The tuning fork is ideal for use either in adhesive and abrasive products as well as in bulk solids with very low density. The position of the switching point can be determined through the length of the tube extension.