Pedestal Heaters

Cast Aluminum Solutions is a leader in designing and manufacturing high-performance pedestal heaters. Excellence is our goal at every step, from needs analysis and initial design, through iterative thermal and structural modeling, to prototyping fabrication and testing, and the transition to high-volume production.

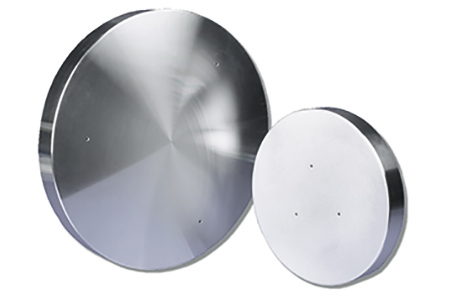

200mm Dia Pedestal Heaters

CAS designs and manufactures custom-engineered high-uniformity pedestals for a variety of processes, including CMP, photolithography, ash/strip, deposition, ion implant, and more.

A cast-in heater offers several performance advantages over competing technologies. With the cast-in design, heating elements maintain intimate contact with the metal substrate, delivering uniform heat transfer and longer overall life, for a lower total cost of ownership.

300mm Dia Pedestal Heaters

CAS designs and manufactures custom-engineered high-uniformity pedestals for a variety of processes, including CMP, photolithography, ash/strip, deposition, ion implant, and more.

A cast-in heater offers several performance advantages over competing technologies. With the cast-in design, heating elements maintain intimate contact with the metal substrate, delivering uniform heat transfer and longer overall life, for a lower total cost of ownership.

450mm Pedestal Heaters

CAS designs and manufactures custom-engineered high-uniformity pedestals for a variety of processes, including CMP, photolithography, ash/strip, deposition, ion implant, and more.

A cast-in heater offers several performance advantages over competing technologies. With the cast-in design, heating elements maintain intimate contact with the metal substrate, delivering uniform heat transfer and longer overall life, for a lower total cost of ownership.

IFC Heated Parts

Cast Aluminum Solutions IFC (Interference Fit Construction) heated parts are ideal for applications

that require materials other than aluminum or exceed the temperature capabilities of cast aluminum.

With FEA (Finite Element Analysis), or if time permits,by an iterative prototyping process,

temperature uniformity levels equaling ±1 percent or better have been achieved.