Level Measurement For Liquids

There are several principles for measuring levels in liquids:

RADAR

Function

In non-contact level measurement with radar, the measuring instrument sends microwave signals from above to the medium, which reflects them. The distance to the product surface is determined on the basis of the microwave signals received by the measuring instrument and the level is calculated. Water and wastewater applications = VEGAPULS WL (S) 61 plics® diversity = VEGAPULS 61 - 66

Numerous process fittings and mounting aids are available for mounting the sensor. The instrument is connected with standard two-wire cable.

As soon as a plausible measured value is found, the corresponding current is output on the signal line. The value corresponds to the current filling level, in relation to the maximum measuring range.

GUIDED RADAR

Function

In level measurement with guided radar, radar pulses are guided along a cable or rod probe and reflected back by the product surface. The measuring probe of the TDR sensor ensures that the signal travels down to the medium undisturbed. This measuring technique is used to measure liquids, bulk solids and interfaces in liquids.

VEGAFLEX 81: with cable up to 75 m, with rod up to 6 m, with coaxial tube (for low-viscosity liquids) up to 6 m

VEGAFLEX 83 for hygienic applications

VEGAFLEX 86 for high temperature and pressure

Numerous process fittings and mounting aids are available for mounting the sensor. The cable versions are equipped with a weight to tension the cable, which can be additionally secured at the bottom of the container. The instrument is connected with standard two-wire cable.

As soon as a plausible measured value is found, the corresponding current is output on the signal line. The value corresponds to the current filling level.

ULTRASONIC

Function

In non-contact ultrasonic level measurement, the sensor emits ultrasonic pulses in the direction of the medium, which reflects them. The time from transmission to reception of the signals is proportional to the level in the vessel. VEGASON 61 = Thread 1½" VEGASON 62 = Thread 2" VEGASON 63 = Flange DN 100

Two thread sizes and mounting aids are available for mounting the ultrasonic sensor. The instrument is connected with standard two-wire cable.

As soon as a plausible measured value is found, the corresponding current is output on the signal line. The value corresponds to the current filling level, in relation to the maximum measuring range.

CAPACITIVE

Function

In capacitive level measurement, capacitive sensor and vessel form the two electrodes of a capacitor. Any change in capacitance due to a level change is converted into a level signal. Measuring probe - with rod up to 6 m - with cable up to 32 m Full or partial insulation determines whether the sensor is used in conductive or non-conductive media

The capacitive probe can be mounted universally. In horizontal round tanks, spherical tanks or other asymmetrical tank shapes, a version with concentric tube is recommended. The instrument is connected with standard two-wire cable.

To be able to display the actual product level, the measured capacitance must be assigned to the percentage height. To carry out this adjustment, the capacitance is entered when the tank is empty and full.

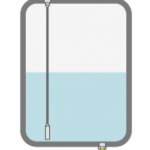

HYDROSTATIC

Function

In hydrostatic level measurement, the measuring cell of the pressure transmitter detects the tiniest changes in hydrostatic pressure, which increases or decreases depending on the level. The acting pressure is converted into an electrical signal and converted into an output signal by the integrated electronics. Submersible pressure transmitter = VEGABAR 86/87, VEGAWELL 52. Compact version = VEGABAR 81, 82, 83 Chemical seal = VEGABAR 81 Ceramic measuring cell = VEGABAR 82, 86, VEGAWELL 52 Metallic measuring cell = VEGABAR 83, 87

The submersible pressure transmitters can be freely suspended above the well or channel or mounted in a process fitting on the vessel. The compact versions are installed directly on the vessel. This can be done from below or from the side. A variety of process fittings and seals allow for a secure installation. The instrument is connected with standard two-wire cable.

As soon as a plausible measured value is found, the corresponding current is output on the signal line. The value corresponds to the current filling level, based on a density value of 1 g/cm³.