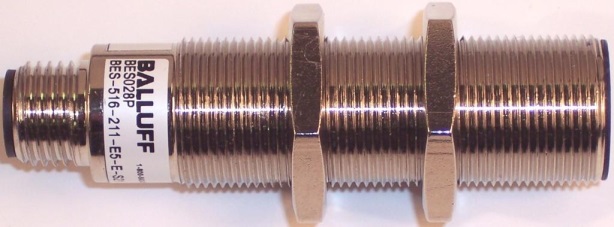

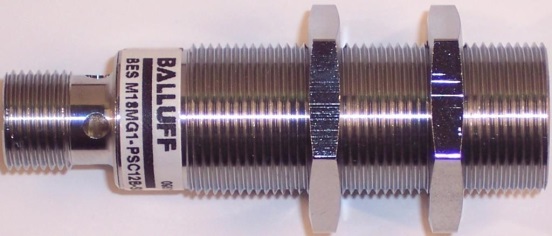

A third and newer type of sensor housing available is sometimes called “quasi-shielded” or “quasi-flush”. This term is used when referring to a sensor that has a “shielded” housing design, yet has to be mounted similar to a “non-shielded” model to achieve its full sensing range. The sensor adjacent is a “quasi-shielded” sensor. As you can see – looks can be deceiving. This sensor looks like a normal “shielded” sensor but it is not. In a “quasi-shielded” model the sensor electronics have been tuned to achieve 3 or 4 times the normal sensing range of a “shielded” sensor. In many cases this is a great advantage as a smaller diameter sensor can be used in place of a larger one. This sensor’s stronger magnetic field balloons down below the metal housing of the sensor and extends much farther out of the face of the sensor. Typically this sensor CAN be mounted “flush”, but it will reduce the sensing distance achieved. To obtain the rated sensing distance (3 or 4 times normal) the sensor face and housing must extend out of its mounting material by an offset distance. The offset distance required for each sensor will be defined by the manufacturer and should be referenced before installation.

To avoid confusion, the main concepts to remember are that the terms shielded, non-shielded, and quasi-shielded refer to the housing design of the inductive proximity sensor. The terms flush, non-flush and quasi-flush refer to the allowable mounting method of the sensor. Looks can be deceiving so make sure you understand the sensor housing design and mounting requirements to avoid unwanted surprises during installation.