Watlow Fluent Heater – Inline heating in a small package

|

Watlow FLUENT®Watlow D4T Data LoggerVEGAPULS 64Vega PLICSCOM BluetoothBaumer PosCon 3DBaumer CombiLyz®Fraser 3014 barTURCK BL ident® |

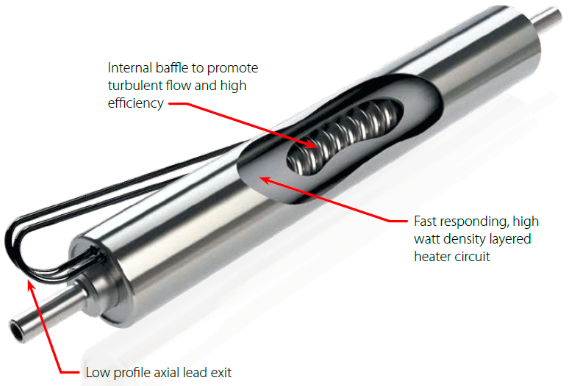

Watlow FLUENT® Provides On Demand Heating in a Small Package

FLUENT is a high watt density, low mass heater that enables on demand heating with an ultra-fast response, leading to higher system performance. The standard construction includes an internal baffle to promote turbulent flow and high efficiency, a fast responding, high watt density layered heater circuit, low profile axial lead exit and an internal thermocouple for high limit control. Powered by Watlow’s patented thermal spray technology, FLUENT makes use of its entire surface to produce heat, which optimizes heat transfer and temperature uniformity.

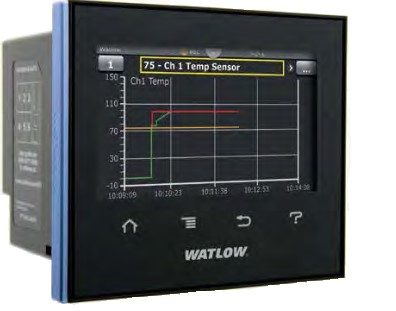

Watlow D4T Data Logger

The D4T with INTUITION® data logger from Watlow® offers a data logger with a wide range of field removable I/O modules for maximum design flexibility. Configurations can be custom tailored to meet the scaling needs of a tremendous range of equipment and applications while providing exactly the hardware types required for compatibility. The D4T data logger also features a 4.3 inch, color, graphical touch panel. Combining power, flexibility and functionality, this new data logger offers unmatched versatility, and its best-in-class ease of use could very well make user manuals a thing of the past.

VEGAPULS 64 for liquids: the smallest antenna ever

Even media with very poor reflective properties, i.e. with a low dielectric constant, can now be measured considerably better than with previous radar sensors. Due to its higher level of measurement certainty, VEGAPULS 64 measures reliably even in applications with foam, turbulent product surface, dirt and condensation. Thanks to its small antenna – the diameter of the smallest version less than 1″ dia – and the resulting compact process fittings, the sensor is an interesting alternative for cramped installation conditions.

Vega PLICSCOM now with Bluetooth

The innovative PLICSCOM display and adjustment module is mounted directly on the sensor for measured value indication, adjustment and diagnostics. This new optional Bluetooth feature allows any transmitter to be adjusted wirelessly from a distance of approximately 25 meters. Your smartphone or tablet provides convenient access to all adjustment functions of the sensor.

Baumer PosCon 3D – Exact and reliable edge measurement

The compact sensor is an efficient alternative to complex laser measuring systems used in different applications where other solutions would fail. PosCon 3D reliably measures edge positions as well as object and gap widths without external software, processing device or reflector. It is easy to install, quick to configure, and low-maintenance in operation.

Baumer CombiLyz® conductivity sensor

The CombiLyz® AFI4/AFI5 is an inductive conductivity transmitter for media analysis, differentiation and separation. It is designed to meet industrial and hygienic requirements in applications with medium to high range conductivity. Thanks to an accuracy of 1% and a Pt100 temperature sensor, CombiLyz® AFI4 provides fast and reliable data and ensures low total cost of ownership.

Fraser 3014 anti-static bar – reduced size, improved performance

For modern machinery and production processes within the operation distance of 20 – 150 mm. Ideal as a more powerful alternative to conventional AC static eliminators.

No need for additional power supply: The 3014 comes with electronics and 7.5 kV fully integrated. Minimum length 250 mm, then in 40 mm steps up to 4010 mm.

TURCK BL ident®, the modular RFID system

Whether used in industrial production, logistics or QA processes, with the BL ident® system from Turck you cover the entire production process from start to finish. All information is centrally available – no matter how rough the application environments are. The data carriers are mounted on all products or containers and identify intermediate and end production stages during the entire production process. They read data before or after relevant production processes or at the end of the production chain.